In today’s highly competitive spirit market, a recognizable outer packaging often determines the “first impression” of the product, and glass liquor bottles are the most common form of whiskey, red wine, alcoholic beverage, rum, gin packaging, and the market demand is also tremendously huge. In addition to the design of the glass spirit bottle itself, the deep processing technology of the glass bottle body – such as spraying, hot stamping, silk screen printing, engraving, etc. – is becoming an important means for brands to create differentiation, improve texture and recognition. So, what are the common deep processing methods for glass spirit bottles? What are the advantages and disadvantages of each process, and what product styles are suitable for different styles of alcohol?

This article will systematically sort out the 10 below mainstream deep processing types and process characteristics of glass container for liquor for you, helping you to create more competitive wine packaging in the market.

Table of Contents

Ⅰ. Painting / Color Spraying

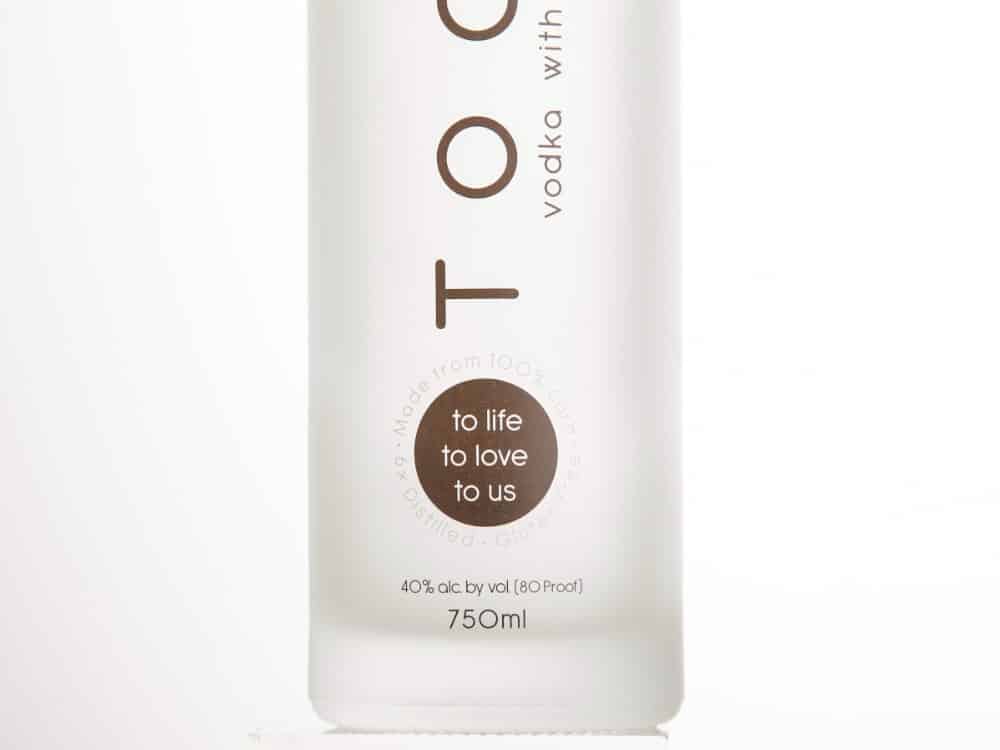

Color spraying is to evenly spray special paint on the surface of the glass bottle, and then bake to fix the coating. It can achieve single color, gradient color, partial spraying and other effects.

Color spraying method: full spray, gradient spray, two-color spray, light-transmitting spray, solid color spray.

Color effect: visual effects such as matte, gloss, pearlescent, metallic, etc., bright colors or high-end texture.

Hand feel effect: At present, high-end products are more pursuing the touch of the glass bottle, and also more tactile paint. Different paints can present different effects, such as the touch of rose petals, velvet, leather effect, etc.

Temperature: Colored on the surface of the glass bottle after baking at about 180-200 degrees. Strong adhesion, not easy to fall off.

Process: Some spraying effects may require more than one spraying to achieve the corresponding effect. For example, solid color metallic red, you need to make a layer of primer first, and then spray the metallic red to present a solid color opaque effect.

Application: The color of the sprayed glass bottle has strong adhesion and can be used in the dishwasher. Simple experimental method, use your fingernails to scratch the colored glass surface without damage.

Precautions:

- The bottle body of the deep processing factory needs to be cleaned before spraying to avoid floating dust or carton debris on the bottle body. Otherwise, the sprayed color will be uneven or have obvious impurities.

- It is necessary to confirm with the glass bottle supplier whether the bottle mouth surface needs to be sprayed with color. If it is used for food and wine packaging, it is recommended not to spray the bottle mouth to prevent the lid from fitting smoothly and scratching the spray layer during the screwing process, affecting the appearance. If the glass bottle is used to fill industrial products, such as hand sanitizer, lotion, etc., you can consider spraying the bottle mouth.

Suitable product style:

Spraying is suitable for seeking economical and affordable deep processing methods. It is like putting a piece of clothing on the clear glass bottle, which changes the style of the transparent bottle to the maximum extent and improves the product grade. It is the first choice for most wine designs. It is also suitable for almost all wines, such as vodka, gin, rum, champagne, tequila etc.

Ⅱ. Screen Printing

At present, large-scale deep processing factories on the market all use fully automatic screen printing machines. This type of printing machine is a device that can print patterns efficiently and accurately on cylindrical or special-shaped containers such as glass spirit bottles and glass cups. It is widely used in packaging fields such as glass alcohol bottles, cosmetic glass bottles, and beverage glass bottles, and is especially suitable for high-end printing needs before the replacement of self-adhesive labels. Small deep processing factories use semi-automatic screen printing machines, which can undertake small batch orders, are simple to operate, and are more flexible.

Process method:

Use special ink to print directly on the surface of the empty glass liquor bottles through the screen, and high-temperature baking makes the ink combine with the glass.

Presentation effect:

The pattern is clear and wear-resistant, and the fonts, LOGOs, and patterns can be printed directly on the glass, and are not easy to fall off.

Precautions: Screen printing has high requirements for the plate. If the font on the layout itself is too small, the printed words may not be clear, or some letters on the layout are indeed. If there is an error in the layout, the entire batch of goods will be wrong. If the ink is too heavy, the letters will be blurred without blank space. Therefore, before mass production, be sure to carefully check the layout and confirm the effect with proofing.

Suitable product style:

Silk screen printing is an indispensable step for products, because each product needs to be printed with product brand logo and capacity, ingredient list, ingredients, storage barcode and other information. Silk screen printing is suitable for almost all products.

Ⅲ. Decal Baking and Offset Printing

Baking is to attach a layer of decorative glaze film with patterns or logos to the surface of rum glass bottles by high temperature or low temperature baking, which is both decorative and durable. Offset printing uses ink to transfer to rubber blanket through printing plate, and then manually transfers the rubber blanket to the surface of glass bottle for vodka one by one, and bakes on the bottle after the rubber blanket is completely dry.

These two processes are currently widely used for pattern and text decoration of liquor bottle glasss, beverage bottles, cosmetic bottles, etc. Baking is not only used on glass alcohol bottles, but also on ceramics and plastic materials. At present, technology is constantly innovating, and more and more effects can be presented.

Notes:

Baking position

Baking is to stick this layer of colored glaze film on the bottle one by one manually. Before production, it is necessary to communicate the position with the spirit bottle manufacturers. But there may be some deviations. Positioning drawing paper can solve this problem, but the cost is relatively high.

Design pattern

According to the LOGO, pattern, and text provided by the customer, the curvature and size of the bottle usually need to be considered. The size cannot be too large or too small.

Baking temperature

The glass bottles for spirits with the printed pattern needs to be sent to the tunnel oven for baking. The temperature that the drawing paper can withstand is also different, which is divided into high-temperature drawing paper and low-temperature drawing paper. The lowest high temperature cannot be lower than 560 degrees, generally around 580. The lowest low-temperature baking temperature is 150 degrees and the highest is 220 degrees, generally around 185 degrees. Baking allows the pigment to melt and adhere firmly to the glass surface. High temperature is more expensive, has strong adhesion, and can be used multiple times, suitable for High-end alcoholic beverage packaging. Low temperature is relatively low and suitable for disposable packaging.

Baking and offset printing are suitable for product styles: Baking is the most popular choice for complex brand patterns. Compared with self-adhesive stickers, baking is directly attached to glass container for liquor, which looks more upscale and can be reused. It is suitable for multi-color patterns, and the bright colors can better express the product. Offset printing is suitable for complex patterns and gradient colors, and can achieve photo-level effects. It is the first choice for collectible products, giving people an artistic enjoyment.

Ⅳ. Hot Stamping

The hot stamping (hot silvering) effect on glass alcohol bottles is achieved through the heat transfer process, which uses high temperature and pressure to transfer the metal foil to the surface of the bottle to form a dazzling metal texture pattern.

Process principle: Using heat transfer technology, first apply a base film, also called primer, on glass bottle for vodka to make the bottle have adhesion. Then use the heated metal mold (hot stamping plate) to stamp the metal foil, so that the foil layer is peeled off and attached to the corresponding base film of the bottle to form a text or pattern effect.

Metal foil material: hot stamping uses gold electrochemical aluminum foil, hot stamping uses silver foil, and other metal reflective effect colors (such as red, blue, purple, etc.) can be customized.

Presentation effect:

The hot stamping effect is very shiny and noble, and is often used for Luxury glass liquor bottle or honey glass bottles, perfume glass bottles, and glass cosmetics bottles. Logos and design patterns can highlight the brand texture and give people a sense of luxury.

Precautions:

Cost control: The larger the area of foil, the higher the cost. The hot stamping effect is usually used for logos or key patterns.

Fineness control: Too fine patterns cannot be made, such as the stamens of flowers and the hair of portraits. You need to confirm with the brand designer to make some simplified debugging effects to see if it can meet the needs of your brand.

Adhesion test: After hot stamping, it needs to pass the wear resistance test (such as alcohol wiping).

Ⅴ. Matte/Frosted Effect

The matte effect on the fancy liquor bottle is a common glass surface decoration treatment, which can not only enhance the beauty and texture of the product, but also has a certain anti-slip function. This effect is mainly achieved through three methods: chemical corrosion (acid etching), sandblasting, and frosted spray paint (imitation frosting).

1. Chemical corrosion (acid etching)

The elegant glass spirits bottle body is immersed in or sprayed with hydrofluoric acid (HF) solution to cause corrosion reaction on the glass surface; for premium liquor bottle that need to be customized with logos, anti-corrosion materials (such as anti-corrosion glue) will be used in advance to cover the areas that do not need to be frosted;

The advantages of the acid etching treatment are uniform, delicate and soft surface effect; it is more suitable for mass production in deep processing plants and has high stability; it can also be used in conjunction with secondary decoration processes such as silk screen printing, hot stamping, and spraying; the cost is relatively low compared to the other two frosted effects.

The disadvantage is that the production process produces a large amount of corrosive liquid, which pollutes the environment and requires waste liquid treatment. At present, many regions prohibit this processing method; in addition, it is not suitable for making complex patterns and the accuracy is limited. It can also cause defects due to improper handling.

2. Frosted spray paint (imitation frosting)

Matte paint is sprayed on the bottle to form a “frosted” visual effect, but it is actually a matte effect of the paint on the bottle, not a real glass surface treatment. The color of this paint can be any color of matte effect, such as matte green, matte powder, etc. It can be sprayed into a frosted effect according to the color number provided by the customer. At present, most matte effects on the market are presented in this way, which is very popular in liquor packaging, cosmetic packaging, perfume packaging, and aromatherapy packaging.

Advantages: Compared with acid etching, frosted spray paint is more environmentally friendly and non-corrosive; low cost, rich color selection; can be used for a variety of artistic effects such as gradient, semi-transparent, and window opening.

Disadvantages: Not scratch-resistant, not washable, easy to lose paint; not as durable and more handy as the real frosted process. It will also expose defects on the glass bottle, such as slight mold oil. The transparent bottle may not be visible with the naked eye. Mold oil, but it is more obvious after spraying matte paint, which leads to a high defective rate and increased costs.

3. Sandblasting (mechanical sandblasting)

Sandblasting is to fix the glass bottle in the sandblasting machine, use high-pressure air to spray quartz sand or alumina particles onto the bottle body, and determine the sandblasting area according to the masking pattern (template). At present, there are not many deep processing factories doing sandblasting, and this method is slowly being eliminated.

Advantages of sandblasting: complex graphics such as local patterns, LOGO, text, etc. can be produced; the surface texture is rough, the graininess is strong, and it is more artistic; it has little pollution to the environment (dry processing) and is safer.

Disadvantages: low efficiency, not suitable for mass production; the surface is not as delicate as the acid etching method; the cost is high, and the equipment and labor requirements are high.

Ⅵ. Electroplating

Electroplating is to plate a layer of metal or metal oxide film on the surface of the bottle to form a reflective or special color effect.

Presentation effect:

Mirror silver, gold, laser color, etc., very eye-catching, with a sense of futurism or luxury.

Application example:

The body of the decorative glass liquor bottle is fully chrome-plated gold, and the champagne bottle is mirror-plated silver.

Ⅶ. Engraving / Laser Etching

Process method:

Use mechanical engraving or laser technology to grind out concave patterns or text on the surface of Luxury packaging bottles for spirits.

Presentation effect:

It has a concave and convex texture, exquisite details, and extremely high durability, giving people an impression of high-end and strong craftsmanship.

Application example:

High-end commemorative whiskey bottles are engraved with years, and limited edition custom shape alcohol bottle laser engraved with exclusive numbers.

Ⅷ. Water Transfer

Water transfer technology is to print the designed pattern on transfer paper with water-based ink, and then soak it in water containing activator to dissolve the pattern layer into a transferable film. The workers then immerse the glass bottles in water one by one, and the pattern film floating on the water automatically wraps the bottle body, and then washes off the residual transfer paper and activator, and finally dries or naturally dries. After water transfer, it is also necessary to spray transparent protective paint (such as PU or UV varnish) to enhance wear resistance and glossiness.

Advantages of water transfer printing

Adapt to complex curved surfaces: can perfectly wrap special-shaped bottles, concave and convex textures (such as frosted bottles, embossed bottles).

Fine patterns: can achieve complex effects such as high-definition photos, gradients, wood grain, marble, etc.

Low cost and small batch: no plate making is required, suitable for customization and small batch production.

Disadvantages

General durability: even with a protective layer, it is easy to lose paint due to bumps and is not easy to preserve for a long time.

The process depends on manual labor: the transfer process requires skilled operation, otherwise bubbles and dislocation are prone to occur.

Environmental issues: the activator contains chemical solvents, and wastewater and waste gas need to be treated.

Cost issues: the single cost is high.

Water transfer printing is suitable for complex shapes and personalized patterns, but it has weak wear resistance and is suitable for scenes where decorative needs are higher than practicality.

Ⅸ. Self-Adhesive Stickers

Self-adhesive stickers (also called self-adhesive labels) are widely used in thick glass liquor bottles, food bottles, cosmetic bottles and other product packaging. They are not only an important carrier for brand identification, but also an effective way to enhance product texture. The production process of self-adhesive stickers is: design → printing → surface treatment (such as lamination, hot stamping) → die-cutting → waste discharge and rewinding, and finally form finished labels that can be automatically or manually labeled.

This is the most economical and affordable method of deep processing on the market. The craftsmanship of various self-adhesive stickers is also ever-changing, and the effects that can be presented are also dazzling. If the wine brand has the ability to purchase large-scale labeling machines, self-adhesive stickers are undoubtedly the most economical and money-saving way. There are also some small labeling factories on the market that provide labeling services for small and medium-sized wine brands. If you need it and don’t want to invest too much in the early stage, you might as well try labeling services.

Presentation effect: generally positive label and reverse label. Some brands will also make a full-body label for the whole circle, which has high requirements on the shape of the bottle, generally a regular cylindrical or square shape. This simple shape can only be considered for self-adhesive stickers. If the bottle body is irregular or has a more advanced design, the self-adhesive stickers will not be able to present the effect well, and more complex processes such as baking, silk screen printing, etc. need to be considered.

Note: The use of machine-applied self-adhesive stickers will have very high requirements for the roundness of the round bottle body. Generally, the glass bottles produced by small glass factories have no inspection standards or lax quality inspection, which may cause the self-adhesive stickers to bubble or not stick properly. Affecting the appearance of the product, wasting self-adhesive stickers will lead to waste and a significant increase in production costs. The same is true for square bottles. If the air pressure is too high during the mold-forming and air-inflating process of the glass bottle during the production process, the bottle wall will bulge after the bottle is formed; and if the mold is not air-inflated enough, it will cause the bottle wall to sag, which is not conducive to labeling. Therefore, the brand must carefully distinguish when selecting the supplier of the outer packaging, and ask the supplier to make a sample for confirmation before making a large quantity of goods.

Application example:

Front and back labels for fruit private label spirits bottles.

Ⅹ. Other Material Decal

Processing method:

Pre-customized plastic, wood, metal and other material decorations are attached to the custom logo glass bottle body through glue or hot melt to achieve different sensory effects.

Presentation effect:

Flexible and rich, large color pattern changes, complex information expression can be made, and the cost is not too high.

Application example:

Collection-level OX, brand joint limited edition olive oil, etc.

In addition, markets in different regions also show a preference for different deep processing effects. For example, in the export to European and American markets, local brands such as vodka and whiskey prefer sandblasting, silk screen printing, and engraving styles; while brandy and champagne brand designs mostly prefer the gorgeous feeling of hot stamping and electroplating to highlight the high-end and scarcity of their own wine brands. Exporting to Southeast Asia and the Middle East markets, due to consumer preferences, they prefer to make do with strong colors, and often choose shiny spraying and electroplating to process their own packaging bottles. Chinese liquor brands, due to their national characteristics, like to spray the bottle body in red (representing joy), yellow (representing nobility), gold (representing wealth) and other effects.

The above 10 deep processing methods are just a rough summary of the different processes and their advantages and disadvantages. If you are designing your own brand for Custom printed glass bottle, you may wish to learn from the selection trends:

High-end wine: Prioritize baking and acid etching (emphasizing permanence and scarcity).

Mass wine: silk screen printing, offset printing (control costs and meet mass production).

Cultural and creative/commemorative wine: water transfer printing, spraying (highlighting personalization).

The deep processing of different styles of custom shape alcohol bottle is developing in the direction of “high appearance + anti-counterfeiting + environmental protection”, and the combination of different processes (such as baking + hot stamping) is becoming more and more common to meet the needs of brand differentiation.

The outer packaging of a wine or alcoholic brand is related to all aspects, from glass bottle design, to various deep processing, to outer box packaging, label design. There is a lot of knowledge involved. If you need professional outer packaging design and glass bottle manufacturer, please contact us.