Turning Packaging Challenges into Brand Opportunities — NEWRAY & Neon Bulgaria

At the start of 2025, a message landed in our Instagram inbox from Neon, an emerging Bulgarian brand specializing in premium aromatherapy and essential oils. While exploring our latest collection of essential oil glass bottles, their attention was instantly captured by one particular design — a sleek, square-shaped glass bottles for aromatherapy oils.

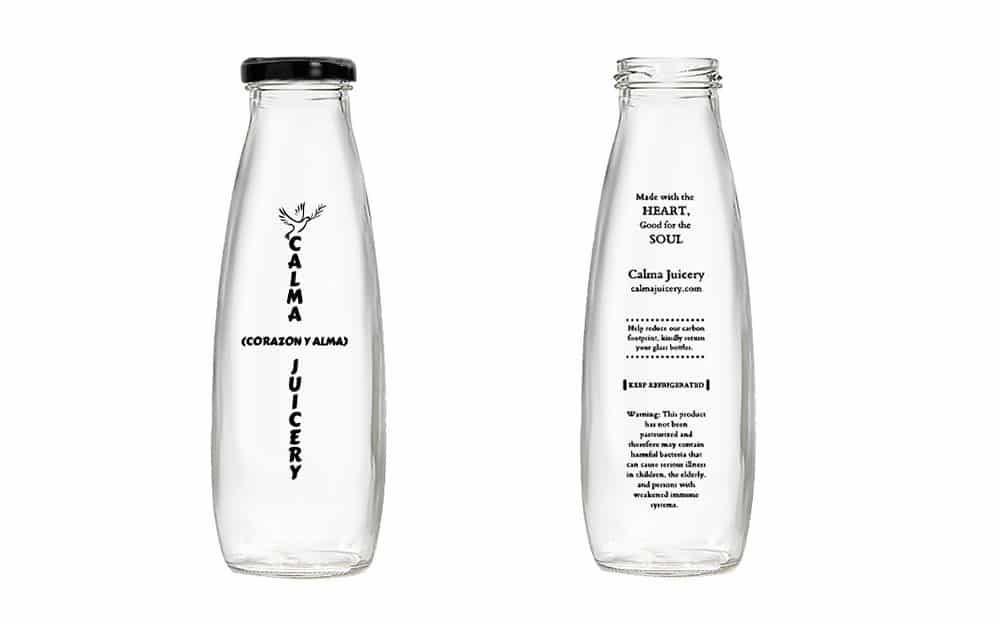

For years, Neon’s product line had featured round shape oil glass bottles. But for their new series, they wanted a fresh, distinctive look that would stand out on shelves and elevate the brand’s premium appeal.

From the first conversation, it was clear: Neon wanted packaging that makes an impact. Within hours, we provided a complete quotation covering 120ml glass bottles, matching droppers, aluminum caps, and even optional custom cards and paper boxes — crafting a full packaging solution. They appreciated the pricing and quickly moved forward.

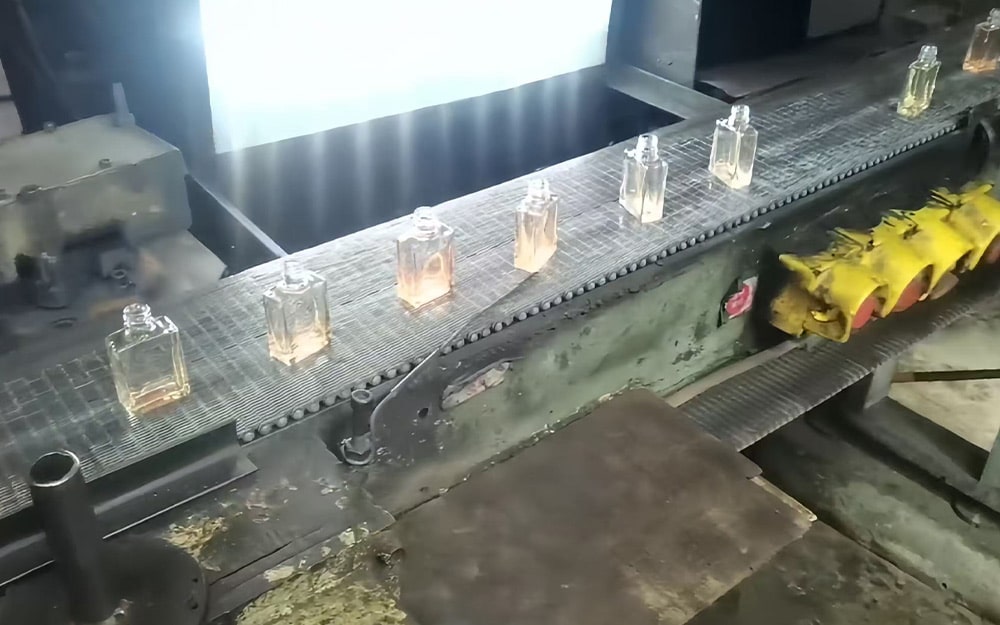

We began with sampling. Each square bottle was finished with a matte spray and precision silk-screen printing, while the packaging featured detailed printing on every side and a UV-embossed logo for extra sophistication. We shared videos of the results, and Neon was thrilled with the transparency, texture, and visual impact.

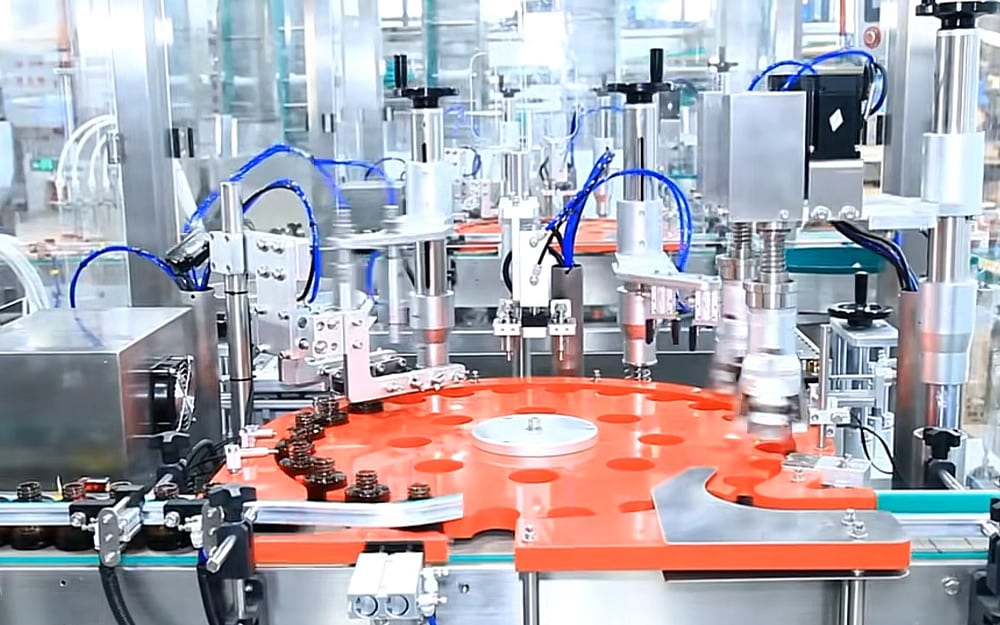

Transparency was key for Neon — they requested complete visibility into production, from bottle forming to spraying, printing, and FDA testing. This not only builds end-customer trust but also reflects the professionalism and process control at NEWRAY. We gladly agreed.

Then came the unexpected twist.

When the first batch arrived in Bulgaria, some bottles leaked during transport from the filling plant to Neon’s warehouse. The team sent urgent photos and videos showing essential oil seeping through cartons, contaminating packaging, and putting nearly 100 bottles at risk. With their launch date approaching, the pressure was on.

We responded immediately. Our technical team hosted a video conference with Neon and the filling plant, analyzing:

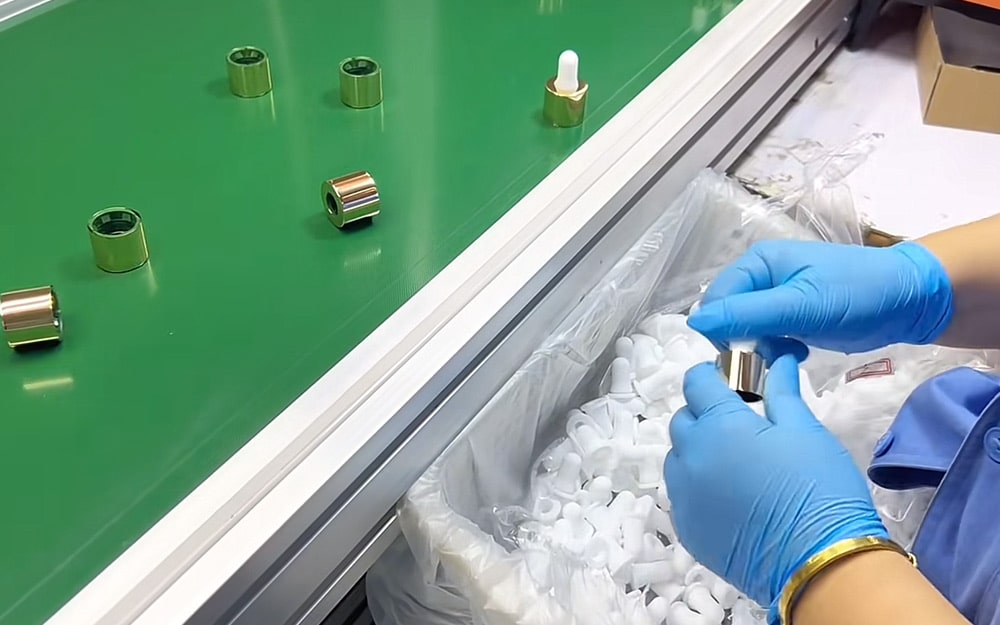

Filling parameters — torque, capping speed, dropper assembly depth.

Bottle mouth precision — flatness and thread accuracy testing.

Component compatibility — rubber tip hardness, resilience, and seal performance.

The culprit? A mismatch between the dropper tip’s hardness and the oil’s fluidity.

Our dual-solution approach:

Option 1: Upgrade the dropper material and adjust hardness for long-distance transport and flat storage.

Option 2: Add a miniature sealing gasket for a double barrier.

New samples were sent immediately. Pressure tests, inversion storage, and week-long local filling trials showed zero leakage. The improved solution was approved, and Neon proceeded with production — plus an additional order for their new packaging series.

The result? The product launched on schedule, the brand image stayed intact, and Neon gained not just a supplier, but a trusted problem-solving partner.

At NEWRAY, we don’t just make bottles — we help brands protect their reputation, elevate their presentation, and deliver with confidence.

Application

Pure essential oils, massage oils, Aromatherapy diffuser oils

Face serums & skin care essences, Hair & nail treatment oils

Herbal medicated oils (e.g., peppermint, camphor)

Perfume base oils

Natural insect repellent oils

Item Description

- Model: 120ml glass square essential oil bottle with droper

- Weight: Bottle:100g

- Capacity: 120ml

- Order Quantity: 10,000 pcs