Christine is a retailer of a gift shop in Malaysia. While browsing our official website, she came across one of our aroma glass bottles and sent us an inquiry, requesting to see a live video through WeChat. After adding her contact, we immediately filmed a detailed video of the diffuser glass bottle, highlighting its transparency, the precision of the reed diffuser bottle neck, and the overall texture. After reviewing it, Christine was very satisfied with the design and quality, and decided to include this decorative glass diffuser bottle in her gift box collection.

Christine mentioned that she had already imported from China multiple times and was very familiar with the process. In addition, she requested customized labels and provided us with the design files. Once all details were confirmed, we quickly moved to sampling. The samples included two sizes, 100ml and 200ml, along with custom-printed stickers. After receiving them, Christine was pleased with both the refillable diffuser glass bottle’s texture and the clarity of the labels, and she soon placed a bulk order.

The first shipment arrived in Malaysia smoothly and was handed over to the local filling plant for filling and labeling. Christine then launched their decorative diffuser on her e-commerce platform. At first, the market response was positive. However, about a month later, Christine informed us that around 10% of end customers reported issues with the labels peeling off during use. This caused Christine great concern, as the appearance of the packaging was critical to the success of her gift sets.

Upon receiving this feedback, our technical team immediately arranged a meeting with Christine and the filling plant to investigate the issue step by step:

Confirming the peeling issue: Based on the photos provided, most cases showed label edges lifting.

Checking bottle surface treatment: We reviewed whether any moisture or oil residue on the glass aroma bottle surface might have affected adhesion.

Evaluating the labeling process: We confirmed with the filling plant the pressure, temperature, and rolling process of the labeling machine, to rule out workmanship problems.

After analysis, we identified the main cause: the adhesive on the labels lacked sufficient resistance to heat and humidity, making it vulnerable in Malaysia’s damp climate.

We proposed two solutions:

Upgrade the label material — recommend synthetic paper or PP labels with a waterproof coating, paired with stronger adhesives resistant to high temperature and humidity.

Optimize the labeling process — advise the filling plant to dehumidify the Eco-Friendly aroma diffuser bottle surface before labeling and increase the rolling pressure to ensure firm adhesion.

We quickly produced improved label samples and conducted simulated tests under high-temperature and high-humidity conditions. The results showed no peeling at all. Christine also carried out long-term local testing, which proved equally reliable. She was very satisfied and decided to switch to the new label solution, while also placing a second batch order.

Application

Luxury home fragrance brands

Gift sets for festivals, weddings, or events

Boutique lifestyle stores

Car fragrance diffuser

DIY fragrance projects

Item Description

- Model: Home Fragrance Diffuser Glass Bottle With Cork

- Weight: 150g & 250g

- Capacity: 100ml & 200ml

- Order Quantity: 5,000pcs & 10,000pcs

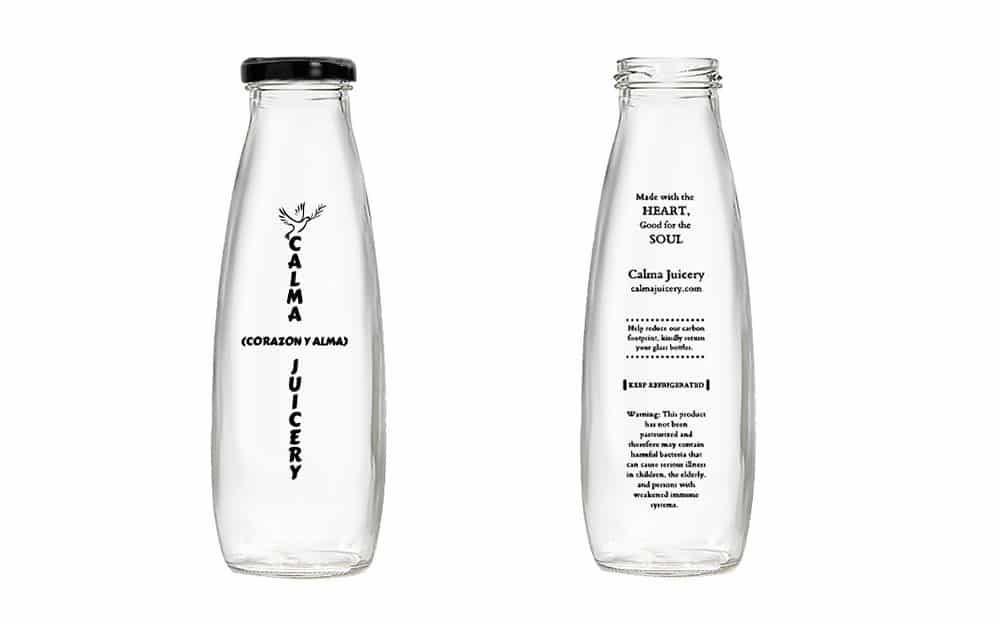

Images