Home » Custom Solution

With over 50 years of experience in custom glass bottles, we have accumulated rich expertise in meeting various customer needs. If you have custom requirements, feel free to contact us. We are here to serve you wholeheartedly.

Practical and innovative glass packaging design is every brand owner’s most effective sales and marketing tool. Newray’s senior designers can provide relevant suggestions to our customers, ensuring the normal functions of the product such as labeling, capping, placement and other factors, while also maintaining aesthetics, fashion and other features. Beautifully designed glass bottles with beautiful shapes, embossed textures, custom coatings and brand embellishments can add color to brand promotional messages.

As a custom glass bottle manufacturer, our glass bottle company knows the appeal of special custom glass bottles for brands. newray is a reliable glass bottle manufacturer, designing special bottle shapes for your brand and providing professional advice and advice on decoration and labeling.

Newray’s labeling factories that we have cooperated with for many years can provide you with more professional suggestions for your brand design, ensuring that the product size, material, appearance, etc. can better fit the design, size, and color of your glass bottle.

While ensuring brand promotion, the labeler also needs to ensure that the adhesive on the label matches the smoothness of the hot and cold spray on the glass bottle, so that it can be foolproof during later use by customers.

In addition to the appearance of glass bottles, we can provide customized outer packaging services for glass bottles to meet the different outer packaging requirements of Amazon suppliers, merchants with drop-shipping services, etc.

Whether you require pallet packaging, carton packaging, or customized personalized packaging, we can appropriately control costs and ensure safety while ensuring that the outer packaging is beautiful and generous to help promote your brand.

Newray provides more professional advice to customers with different needs, allowing customers to spend their money well.

You only need to provide a freehand sketch or explain their design idea to our sales team.

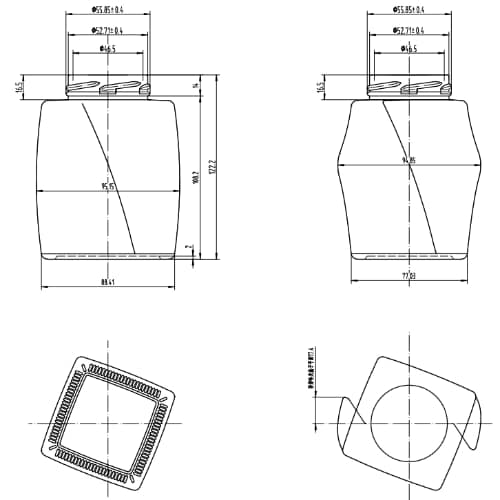

Our designer works based on your information and provides the initial drawing within 24 hours. Any necessary changes will result in a revised drawing within the next 24 hours. Once everything is confirmed, we proceed to the next step.

Upon your confirmation of the drawing, our designer will supply a 3D mock-up for your review. If you wish to inspect the 3D-printed bottle, we can provide it within 3 days at a cost of only 50 USD.

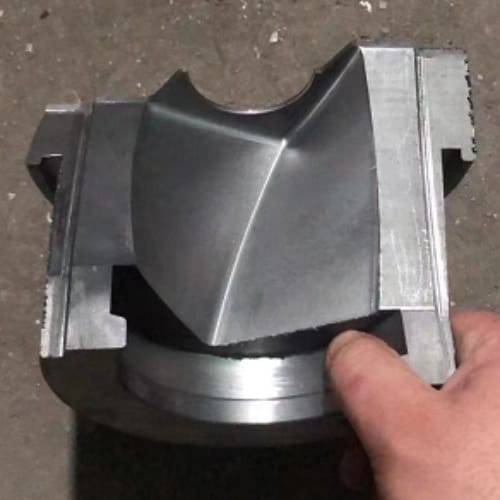

Once the design is confirmed, we can proceed to construct the mold, a process that typically takes only 15-20 days. The mold fee is determined based on the design and volume of the bottles.

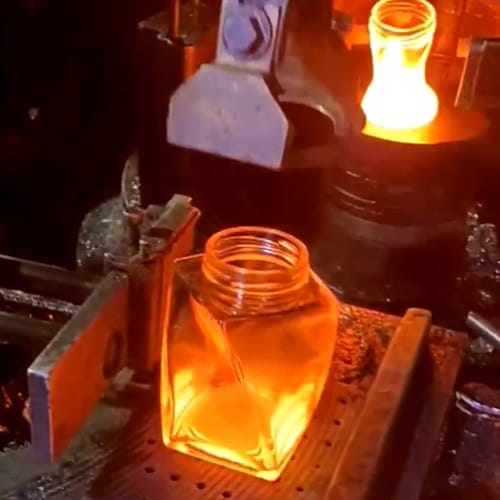

Once the mold is ready, we will arrange for the sampling of the mold, a process that typically takes 15-20 days. At this stage, you can have the actual bottles in their hands and still have the opportunity to make design changes if needed.

If you are satisfied with the design and pleased with the actual bottle, you can proceed to place your order.