Jamie, the owner of a U.S. premium tea brand, first connected with us on Instagram after receiving our glass jars with lids catalog. He was surprised to find one model identical to the same glass tea storage container jar he had been using. This led to a deeper discussion, as Jamie shared a long-standing issue with his existing supplier: the metal lids imported from India failed to provide airtight tea packaging, causing his teas to lose aroma and flavor after just one month of storage. For a high-end tea brand, this was a serious risk to customer experience and brand reputation.

To get to the root cause, Jamie sent us samples of his glass jars for tea leaf and lids for detailed analysis. Our engineering team carried out a three-step investigation:

- Precision Measurement– Using 3D measurement, we confirmed that the glass jar openings fully complied with international standards, eliminating the jar itself as the cause.

- Compatibility Testing– We matched Jamie’s lids with our standard jars and detected slight thread tolerance differences. While subtle, this presented a potential sealing risk.

- Core Analysis– The key issue was identified in the lid’s inner seal. Thickness gauge testing showed an average of only 0.3mm, unevenly applied—well below the 0.5mm standard required for reliable tea storage solutions. A compression rebound test further revealed poor elasticity, meaning the seal could not maintain lasting pressure under temperature changes, allowing moisture to slowly penetrate.

Conclusion: The sealing problem was caused by insufficient seal thickness, poor material quality, and tolerance mismatch.

Based on these findings, we proposed a solution:

- Replace the existing liner with a food-grade sealoffering better elasticity and resilience.

- Increase the seal layer to 0.5mm with uniform distribution for consistent airtight performance.

- Conduct pre-shipment compatibility testing between jars and lids to prevent future mismatches.

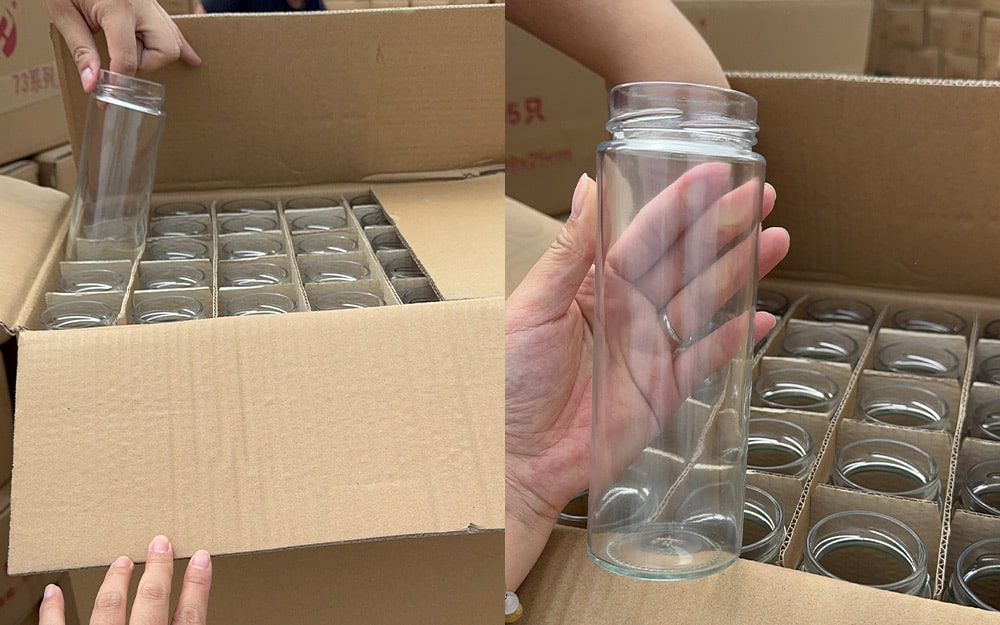

To validate the improvements, we produced custom glass tea storage jar samples and performed a 48-hour high-humidity simulation test. The results were clear—the tea remained dry, fresh, and aromatic. Impressed by the data and real performance, Jamie placed an initial order of 5,000 sets of custom tea glass containers with improved lids. A few months later, he reported excellent market feedback: consumers noticed longer freshness and better flavor, leading to repeat purchases. Jamie has since expanded his orders and continues to rely on us for his tea packaging needs.

This case highlights how precise testing, material expertise, and packaging innovation can transform a challenge into a success. For tea brands seeking reliable airtight tea glass packaging and premium glass jars with lids, we provide not just containers, but complete, tested, and proven tea storage solutions.

Application

Packaging for Tea, Honey, Nuts, Pickles, Ghee, Cheese

Item Description

- Model: 380ml Glass Ergo Jar With Metal Lid

- Weight: 250g

- Capacity: 380ml

- Order Quantity: 5000PCS