Table of Contents

When it comes to glass, people always associate it with beauty: the crystal clearness reflects the colorful world, it is a magician of light and shadow, reflecting the beauty of all things. However, the transparent body of glass with a water-like texture hides endless stories. Next, let’s learn about how they were born in combination with the glass products that follow you like a shadow.

Glassware Drinking Glasses

Glassware drinking glasses is a necessary commodity for human life made of glass, including highball glass, beer glasses, mugs and so on.

Daily glass – it is a substance that has neither free electrons nor easily excited electrons in its structure. The structure of the substance is very compact, without many pores and other conditions. The characteristics of this material make the glass crystal clear, making people feel clear and comfortable at first glance; At the same time, its inert properties give it strong acid and alkali resistance, so you don’t have to worry about harmful chemicals infiltrating the contents; Due to its 100% recycle, it has become widely recognized as the safest, healthiest, and most environmentally friendly food packaging, container, and household product in the world.

In the hot summer, people will truly experience the crystal clear and refreshing feeling when drinking frozen drinks and shaved ice in glass bottles, glasses or glass plates; ten-color fruit pieces or various vegetable shreds are filled in various exquisite, clean and bright glassware, fresh and bright, no matter from which angle, up, down, left, right, you can see it clearly; food pays attention to color, fragrance and taste, and glass tableware, wine utensils, and kitchen utensils become your most ideal utensils. All of these will allow you to enjoy the elegant taste and vision, as well as the peace after the soul is cleansed and purified.

Today we will visit how beautiful and safe glassware was born and learn about the stories behind them. The first thing we need to tell you is its composition, production process and production technology.

What is glass?

Glassware is mostly made of soda-lime silicate glass, borosilicate glass, potassium-barium crystal glass, etc., and a small amount is made of microcrystalline glass, high aluminum glass and some special glass.

What are the process of making glass?

The production of glassware mainly involves four steps: batching, melting, forming annealing, and processing. Glass can be colorless and transparent, or transparent and colored. These colored glasses are produced by adding a very small amount of metal elements to the glass raw materials and melting them together. For example, cuprous oxide can produce red, green, or blue.

You may also see many beautiful glass products such as carvings and printings. They are formed by various surface processing according to the aesthetic needs of different consumers. For example, potassium-barium crystal glass is mostly used to make high-end artistic utensils such as goblets, perfume bottles, fruit basins, vases, etc. The cooking, microwave, and oven utensils you use, such as coffee pots, baking trays, heat-resistant fresh-keeping boxes, etc., are made of heat-resistant borosilicate glass, while kitchen utensils that can be burned directly with flames are made of microcrystalline glass, which has better heat resistance and resistance to temperature changes.

Typical molding process of glassware

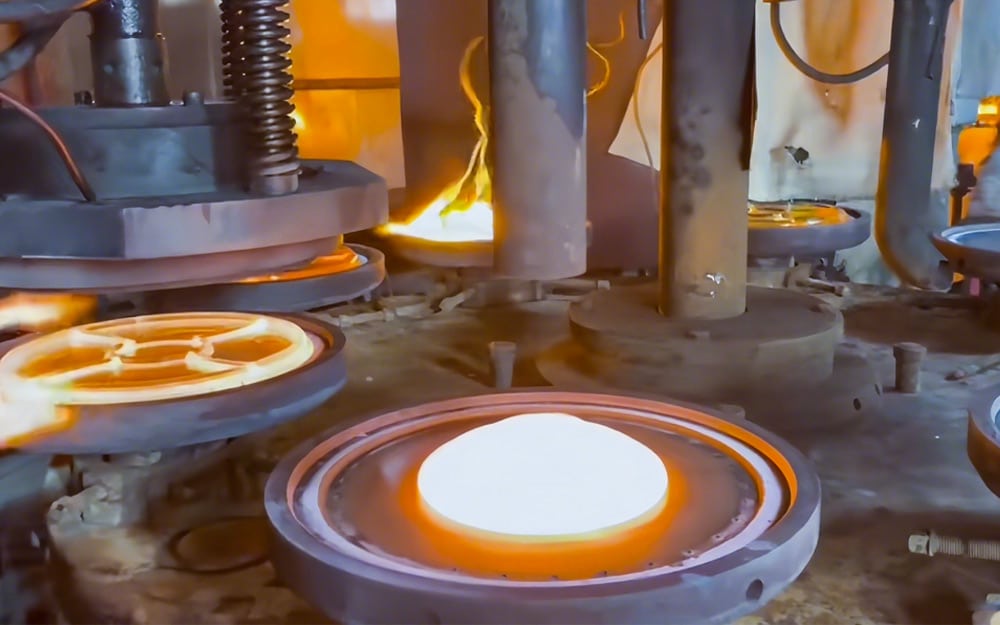

Put the glass raw materials configured according to the requirements into the kiln for melting. After melting, clarify it into a uniform glass liquid without bubbles, stones, or stripes, cool it to the viscosity range required by the corresponding molding method, and then perform various molding operations.

Blowing molding

There are two ways of blowing molding: manual and mechanical blowing molding.

During manual molding, a hand-held blowpipe is used to pick up materials from the crucible or the material intake of the pool kiln, and blow them into the shape of the vessel in the mold. The rotary blowing method is used for smooth round products; the static blowing method is used for products with convex and concave patterns on the surface or non-circular shapes.

First, pick up colorless materials and blow them into small bubbles, and then use small bubbles to pick up color materials or opacified materials and blow them into the shape of the vessel. It is called jacket blowing. Use color fusible material particles to stick to the opacified jacket material, and various colors will naturally melt and flow, which can be blown into natural scenery vessels; stick ribbon-shaped opacified materials on the color material, which can be blown into wire drawing or wire winding vessels.

Mechanical molding is used to blow large quantities of products. After receiving the material, the blowing machine automatically closes the iron mold and blows it into the shape of the vessel. After demolding, the cap is removed to form the vessel.

Press-blow molding can also be used. First, the material is punched into small bubbles (prototypes), and then it is blown into the shape of the vessel. It is more efficient and of better quality than blowing with a blowing machine alone.

Pressing molding

During manual molding, the material is manually picked and cut into the iron mold, the punch is driven, pressed into the shape of the vessel, and demolded after solidification. Mechanical molding is automated production, with large batches and high efficiency. Pressing molding is suitable for products with large mouths and small bottoms that can be removed from the punch, such as cups, plates, ashtrays, etc.

Centrifugal molding: The material is received in the rotating mold, and the centrifugal force generated by the rotation causes the glass to unfold and cling to the mold, and is taken out after solidification. It is suitable for the molding of large glassware with uniform walls.

Free molding

Also known as moldless molding. The material is manually picked and repeatedly baked, modified or hot-bonded in front of the kiln.

Because it does not contact the mold, the glass surface is bright and the shape and lines of the product are smooth. The finished product is also called kiln glass products. Typical products include glass crafts and decorations.

Processing

After forming, the glassware must be annealed to eliminate the thermal stress caused by uneven cooling. Ordinary pressed products and kiln glass products with simple shapes do not need to be processed anymore. Most glassware undergoes various processing after forming to complete the shape of the products and have artistic effects. Such as: carving, tempering, polishing, rough surface delustering, glaze decoration, rainbow decoration, gold decoration, ion diffusion coloring, etc., mainly for the external processing of the vessel. Through optical principles, the user feels that the entire vessel exudes a mysterious halo from the inside to the outside.

Glass is beautiful. Nowadays, people’s lives are becoming more and more affluent, and the trend of pursuing beauty is unstoppable. Glass products that are becoming more and more beautiful, safe, healthy and environmentally friendly naturally become an important goal for people to pursue high-end enjoyment!