Table of Contents

Ⅰ. Introduction

For decades, it’s no exaggeration to say that the wine industry has been burdened by tradition. Glass bottles have consistently been the heaviest form of wine packaging. A standard 1000ml wine or champagne bottle produced by a typical glass bottle factory typically weighs 600 to 800g, resulting in staggering logistics costs and a significant carbon footprint. This is despite the enormous global market for wine, sparkling wine, and champagne. If global alcoholic beverage consumption is converted to standard 1000ml glass bottles, wine consumption in 2024 will reach 22.1 billion liters, requiring approximately 22.1 billion bottles annually. Global sparkling wine consumption will reach 5.4 billion liters, equivalent to 5.4 billion bottles entering the supply chain. Champagne, the most representative of this category, despite limited production areas and production, still boasts annual sales of 240 million liters, requiring 240 million glass bottles.

These nearly 28 billion red wine bottles are undoubtedly a significant number. With sustainable development, green environmental protection, and governments striving to reduce carbon emissions becoming core priorities for global brands, coupled with rising supply chain costs and the post-pandemic economic contraction, the demand for lightweight glass solutions for wine packaging is unprecedentedly strong. Imagine if even a 10g reduction in weight per bottle could save 280 million tons of glass, a significant energy saving.

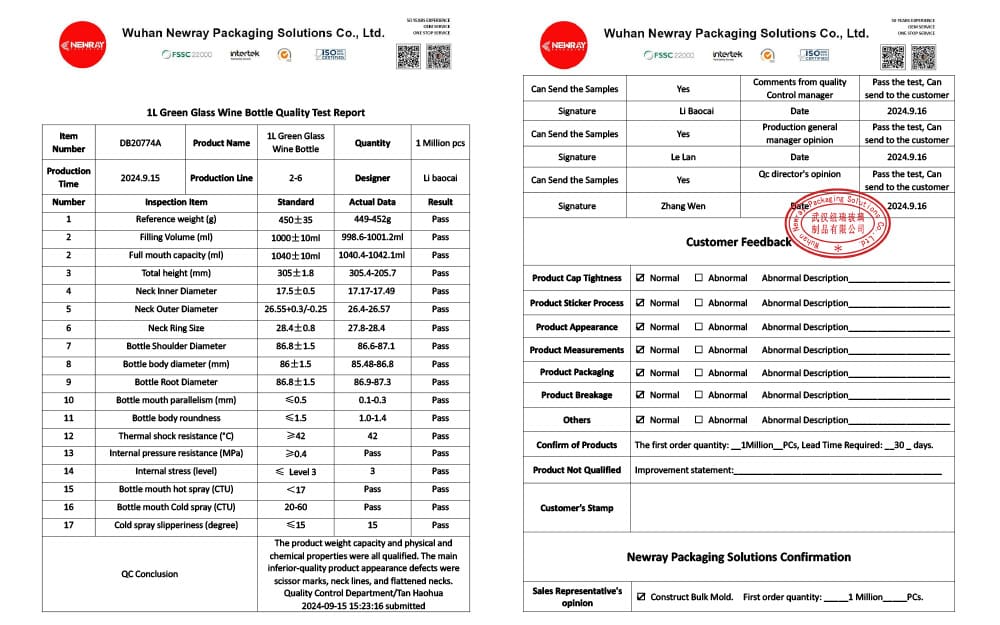

At NEWRAY Glass Packaging, our design and production teams collaborated to address this challenge with a groundbreaking innovation: a green, 1000ml wine bottle weighing only 450g has passed quality inspection and has been shipped to European customers for filling tests, with no issues. This represents a 300g reduction from the original 750g weight, while maintaining strength, stability, and impact resistance, and achieving perfect bottle uniformity. Our team used Narrow Neck Press and Blow (NNPB) technology to reduce the weight. This technology is only available in two or three factories in China. Detailed inspection data for this product follows:

This isn’t just a minor improvement; it’s a fundamental rethinking of glass manufacturing. Here’s how we achieved it.

Ⅱ. The Challenge of Lightweighting

Lightweighting glass is an engineering balancing act, requiring coordinated efforts across multiple departments. From drawing planning to mold design and production adjustments, it demands perfect collaboration and bold experimentation. Reducing the amount of glass used can compromise the structural integrity of the bottle. Improper design or substandard production techniques can significantly reduce production yields, leading to higher breakage rates and instability during use, resulting in poor user experiences like bottle bursts and shatters. Newray understands the significant risks inherent in lightweight design. However, to further reduce carbon emissions and provide customers with superior service in the competitive market, the Newray team is committed to exploring high-tech innovations. This is also a major step in driving industry development.

Achieving ultra-lightweighting requires innovation at multiple stages of design and production. Here are four key aspects of Newray’s successful 450g lightweight wine bottle:

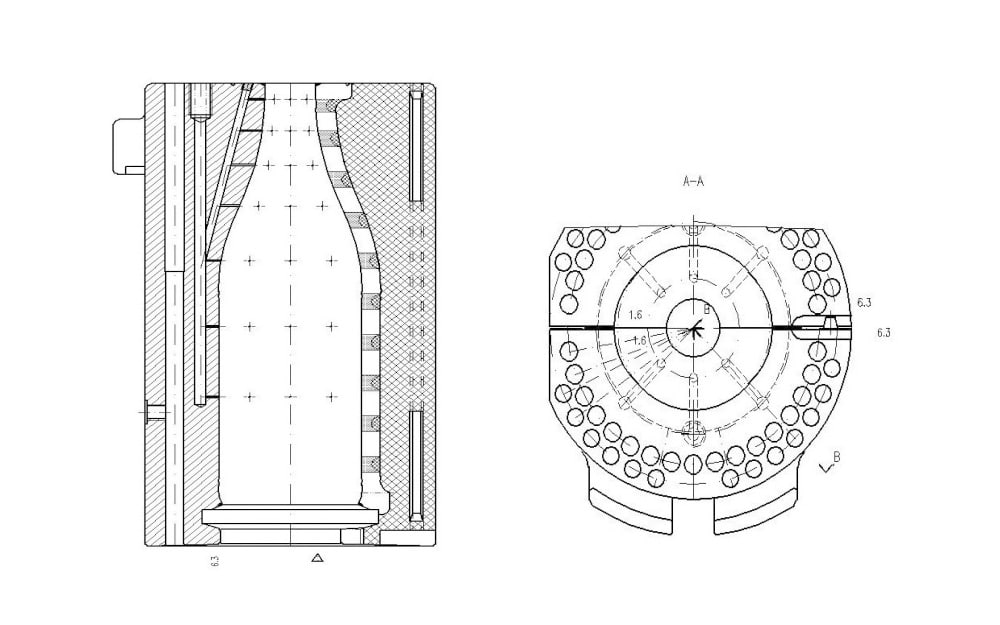

1. Advanced glass formulation and precision molding

It all starts with the glass itself. In terms of formulation, we rigorously control the quality of the raw materials, using an optimal content of silica and modifiers. This enhances the glass’s material properties, making it more durable and enabling lightweight molding, thinner walls, while maintaining thermal shock and impact resistance.

Combined with this advanced formulation is precise in-mold pressure management. By precisely controlling the air pressure within the mold during the molding process, we ensure uniform distribution of the glass. This eliminates weak points and maintains consistent thickness throughout the bottle body and base.

2. Structural Optimization Using Finite Element Analysis (FEA)

Before each bottle is produced, its design is refined digitally. Our engineering team uses computer-aided design (CAD) and finite element analysis (FEA) software to simulate stresses, pressures, and impact points.

Engineers optimized every curve:

- The concave groove (upturn) at the base is carefully designed to distribute vertical loads.

- The shoulder and heel angles are designed to direct external impact forces to critical areas.

- By slightly widening the bottom profile, the overall center of gravity is lowered, ensuring superior stability on shelves and tables while reducing weight.

This scientific approach ensures that every gram of glass contributes to its structural function.

3. Surface Coating Technology Enhances Strength

Thinner glass is more susceptible to surface microcracks, which can become points of failure. To address this, we employ a two-stage coating process:

Hot End Coating (HEC): Applied immediately after forming, this thin tin oxide coating protects the bottle and prepares it for the next stage.

Cold End Coating (CEC): A specialized polymer coating is applied after annealing. This significantly improves surface lubricity, reducing scratches and wear during filling, labeling, and shipping. This coating is a critical barrier, increasing burst strength and overall durability by up to 30%. Some factories in China even skip this step to reduce production costs, significantly increasing bottle breakage rates.

4. High-speed, automated production ensures consistency

Precision engineering requires precision manufacturing. Our advanced equipment includes servo drives and closed-loop control systems. They ensure that each glass bottle is delivered at a precise weight and temperature, and that each bottle is formed with repeatable precision at high production speeds. This automated technology ensures that every 450g bottle leaving our production line is identical, meeting the stringent tolerances required for safe filling and shipping on modern, high-speed bottling lines. This is particularly important given the extreme precision required for precision, especially in fully automated machines. Imagine if the weight of the outer glass bottles wasn’t precisely controlled, resulting in significant variations in each bottle, which would lead to significant variations in the fill volume. This is unacceptable in some countries, and brands could face significant fines.

Ⅲ: Beyond the Breakthrough: Bringing Tangible Value to Your Brand

This lightweighting breakthrough will provide immediate benefits to wine producers and brand owners:

Significant Cost Reductions:

Reduce raw material usage by over 25%. Significantly reduce freight costs—transporting a container of empty bottles is significantly more efficient, allowing you to ship more finished goods per shipment. Imagine if a company that uses over 10 million wine bottles a year could save 20% on the cost of a glass bottle, how much profit growth it could bring to the company.

Superior Sustainability:

Lower weight means a significantly reduced carbon footprint, from manufacturing (less energy) to transportation (less fuel). This enables your brand to make verifiable ESG claims and attract environmentally conscious consumers.

Excellent Performance:

Our bottles undergo rigorous internal pressure, vertical load, and impact testing. They are designed to operate flawlessly on filling lines and withstand the complexities of global logistics.

Marketability:

Lightweight doesn’t mean “cheap.” Brands can highlight their bottles as lighter and more environmentally friendly in advertising, enhancing brand power.

Ⅳ. Slimming down your glass packaging is the answer to the times

The birth of the 450g wine bottle demonstrates that if manufacturers are willing to invest more effort in production innovation, boldly experiment, integrate economic goals with environmental responsibility, and assume greater social responsibility, they can not only make a significant contribution to their customers but also have a significant impact on society as a whole. While serving society, they can also reduce carbon emissions and protect the environment.

At NEWRY, we believe the future of glass packaging is smart, lightweight, and sustainable. We also offer a range of surface treatments, including screen printing, spray painting, and decals, ensuring your wine bottle enhances your brand’s premium positioning. Ready to reduce your packaging costs, lower your environmental impact, and cut logistics expenses? Contact NEWRAY today for samples and detailed technical information. We’ll show you how our lightweight glass solutions can enhance your brand and profitability.